SK508 SV980 SV882 Micro-scale humidification ultrasonic dry mist fog dust suppression nozzle

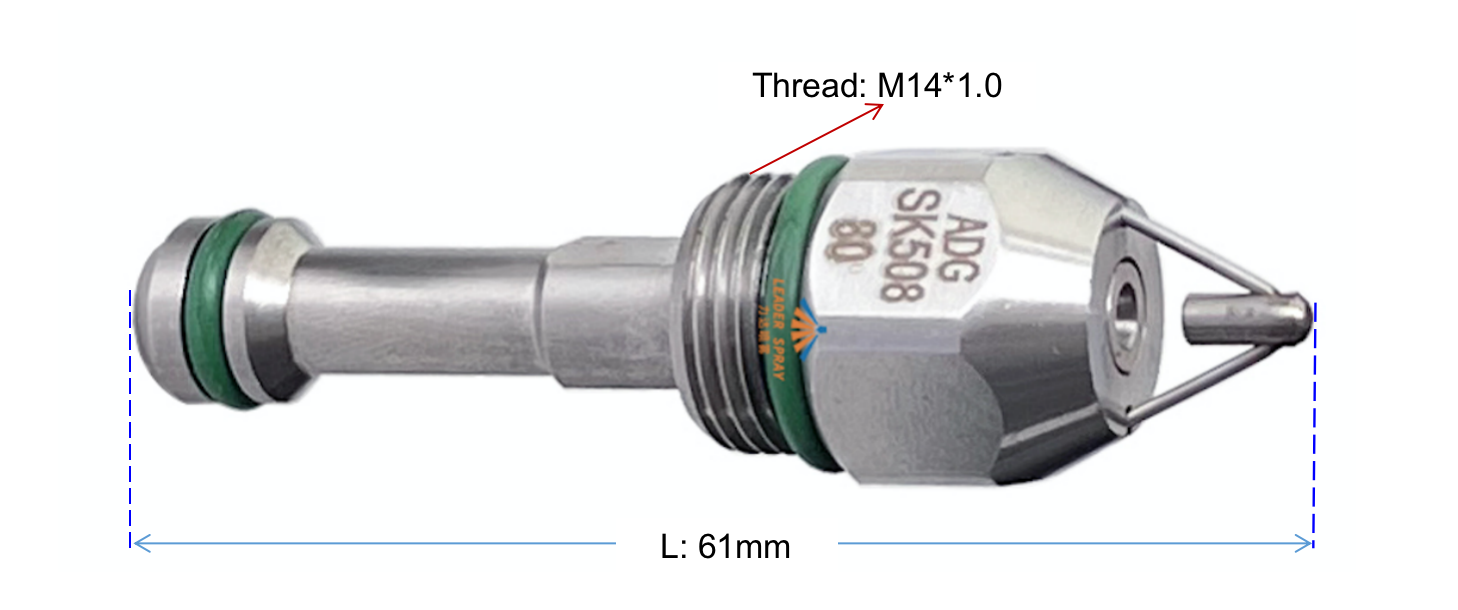

● Connection: 1/8 & 1/4 inch Female thread

● Pressure internal mixing type

● Stainless steel material

● Accept sample order (1-2 pieces)

● Shipping time: 1 week after pay

Product feature:

● Connection: 1/8 & 1/4 inch Female thread

● Air and water are mixed to produce atomization

● The ultrasonic wave is generated by the vibration of the vibrating head in the front section of the nozzle

● The second atomization is fully atomized and the particles are finer

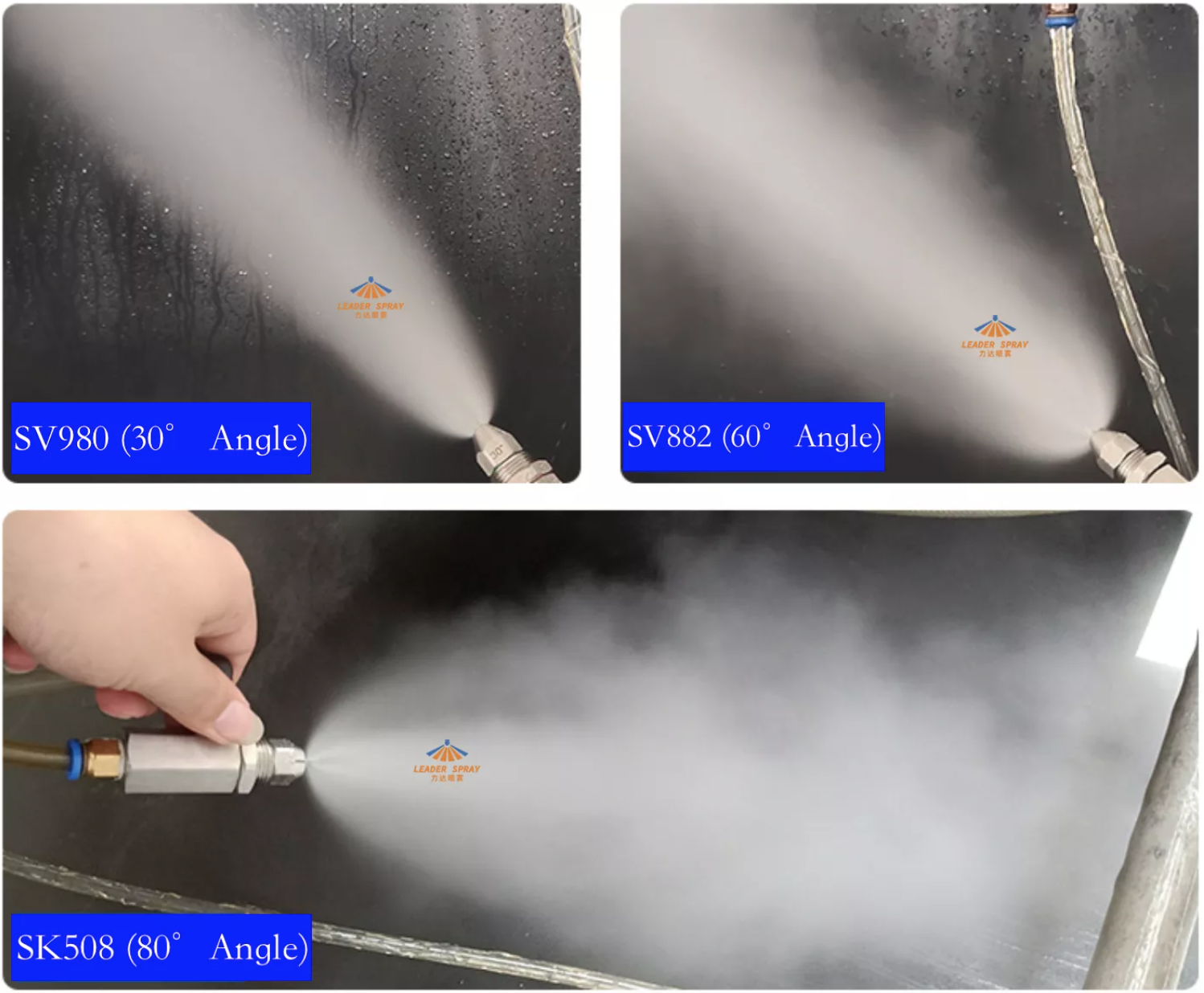

● There are three spray angles: 80 degree, 60 degree and 30 degree.

Ultrasonic nozzle series: The nozzle is precision machined with stainless steel material, and the atomized spray is ultrasonic spray. The average atomized particle is less than 10 microns.

There are two installation methods: ordinary installation and thin-walled installation. The thin-wall installation size is M20*1.5mm, the air inlet is 1/4, and the water inlet is 1/8. Can also be customized according to customer requirements.

Uses: Widely used in coal plant vibrating screen, coal mine dust removal, conveyor belt, dumper, spray humidification, PM2.5 treatment, environmental humidification, disinfection and sterilization, cooling and cooling, film spraying, dry fog dust reduction system, etc., the dust removal efficiency is about 95% . It can be used with micron dry fog dust suppression device.

Ultrasonic atomization nozzle, the atomization process is divided into two stages. In the first stage, the liquid is first mixed with compressed air to produce fine atomized droplets that are ejected out of the nozzle. When the atomized droplets hit the ultrasonic generator at the front of the nozzle Immediate re-micro-atomization into smaller droplets is called the second stage.

In fact, the advantage is that a specially designed ultrasonic generator is installed at the front end of the nozzle, which uses the energy of the fluid hitting the metal at high speed to make the ultrasonic generator oscillate at a high frequency and micro-atomize the atomized droplets again. Such a delicate design not only It can generate extremely tiny atomized particles. Compared with the general two-fluid nozzle, the spray particle size produced by this series of ultrasonic atomizing nozzles is more uniform and the atomization effect is more ideal.

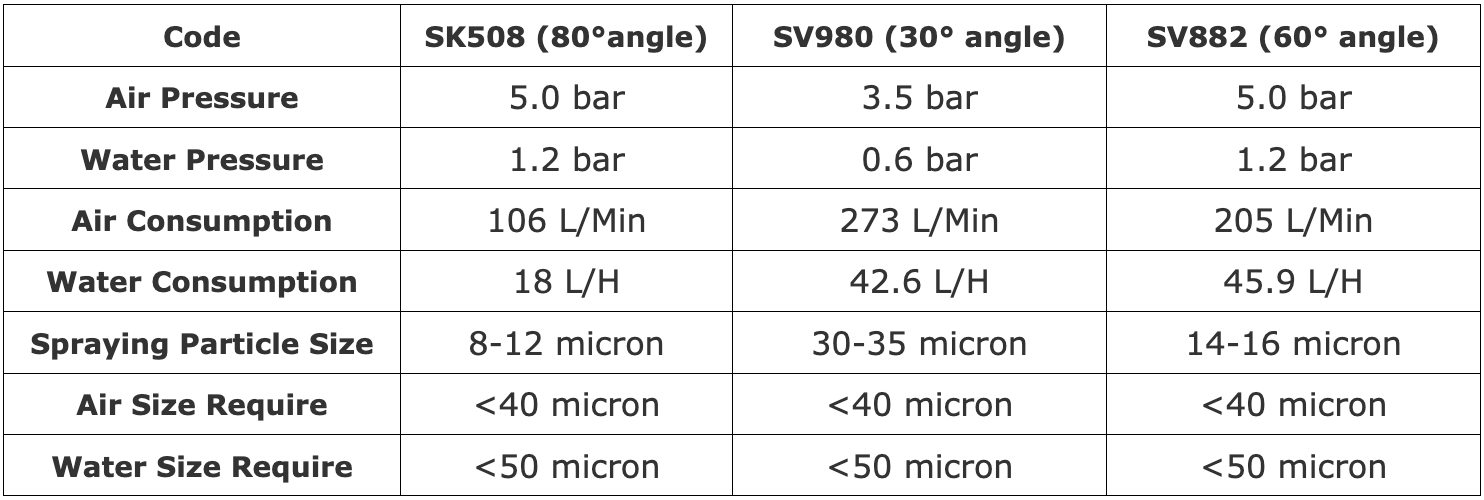

Technical data of the atomizer:

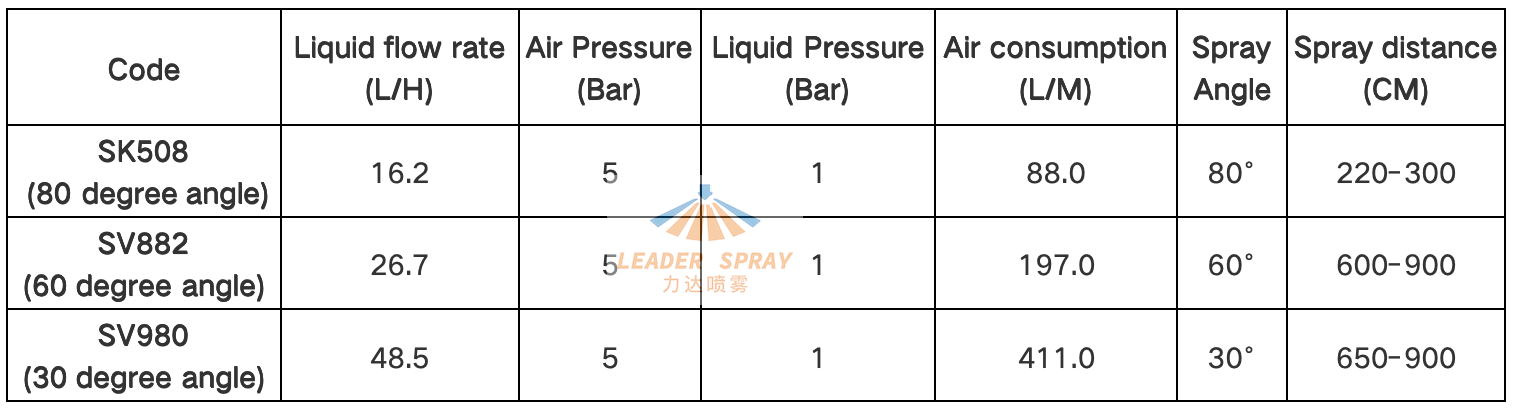

More testing datas:

Products pictures:

Pneumatic Atomizing Nozzles

Applications:

1. Air humidification;

2. Chemical processing;

3. Chemical spraying;

4. Liquid spraying;

5. Tobacco humidification;

6. Flue gas evaporation and cooling;

7. Sterilization and Disinfection;

8. Cooling parts;

9. Spraying, lubricants.

Certifications